Damage Localization in Wind Turbine Blades by Non-destructive Testing and Machine Learning

Summary

Acoustic emission testing is a well-known non-destructive testing technique adopted in Aerospace and Civil engineering. The progression of damage is typically accompanied by the emission of characteristic sounds and vibrations. Sensors have been developed to ‘listen’ to these acoustic emissions and localize them by triangulation. In this study, machine learning techniques (supervised learning) will be employed to extract the acoustic source location from recorded acoustic emissions.

Business need

Wind turbines have seen a dramatic increase in size and are being installed at larger offshore distances than ever before. Down time, inspection, or replacement of components is becoming increasingly challenging and expensive as a result. This need is driving the development of structural health monitoring (SHM) technologies that allow early detection of deteriorating structural integrity. A main roadblock for such systems is their reliability. False alarms alarms, i.e. wrong indications of damage on components, can become very expensive and quickly eliminate the business case for such systems. By combining damage detection with damage localisation, the accuracy and therefore value of such a system rises dramatically.

Concept

The concept is to generate a set of training data for different locations on / inside a blade structure and record the response with a microphone at the root end of the blade. The recorded information will then be used to train a machine learning model to predict damage positions based on sound emissions. The recorded data will be pre-processed to extract a maximum of information in an efficient way. One possibility is to package the data into in time-frequency diagrams with the objective to train and generalize a model of source location as a function of 2D features in the time-frequency diagrams.

Previous research

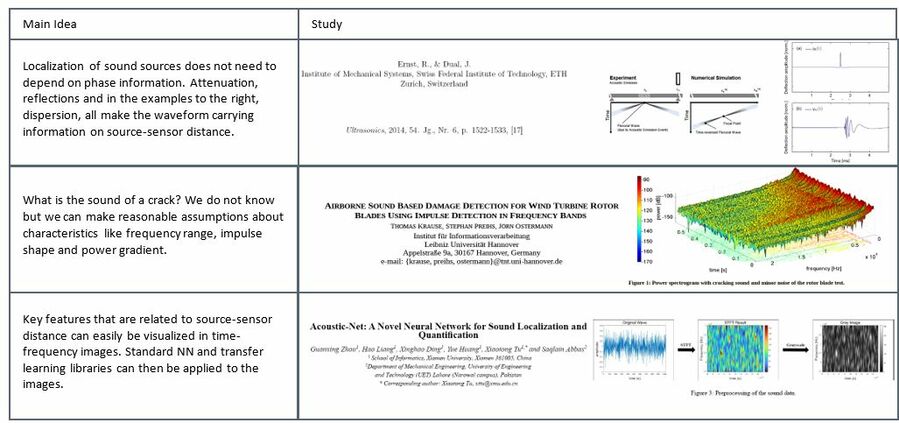

The project will be kicked-off by a literature research. Especially, the following three studies will be of interest:

Scope definition, project plan

We are looking for a student that will explore the feasibility of acoustic emission source localisation within a supervised learning framework. Depending on the student's interest the work can focus on simulation, programming or experimentation.

The project will be divided into the following main steps:

1. Literature study

2. Simple simulations on 1D structures (Comsol/Matlab) to create training data and get familiar with the problem.

3. Supervised learning from set of simulated data and numerical experimentation with different scenarios.

4. Recording of experimental data on real blade structures.

5. Model selection and validation.

6. Conclusion and outlook for further work.

Above order is only a suggestion, the final scope will be agreed with the student. The project will make the student familiar with wave propagation in fluids and structures, wind turbine design, composite materials, numerical modelling and data science. It would be welcomed if the student could visit a blade manufacturing site in Denmark as part of the study.

Project delivery, support, and examination: TBD:

Project governance: TBD.

Contact: Thierry Baasch (Assistant Professor) Thierry.Baasch@bme.lth.se